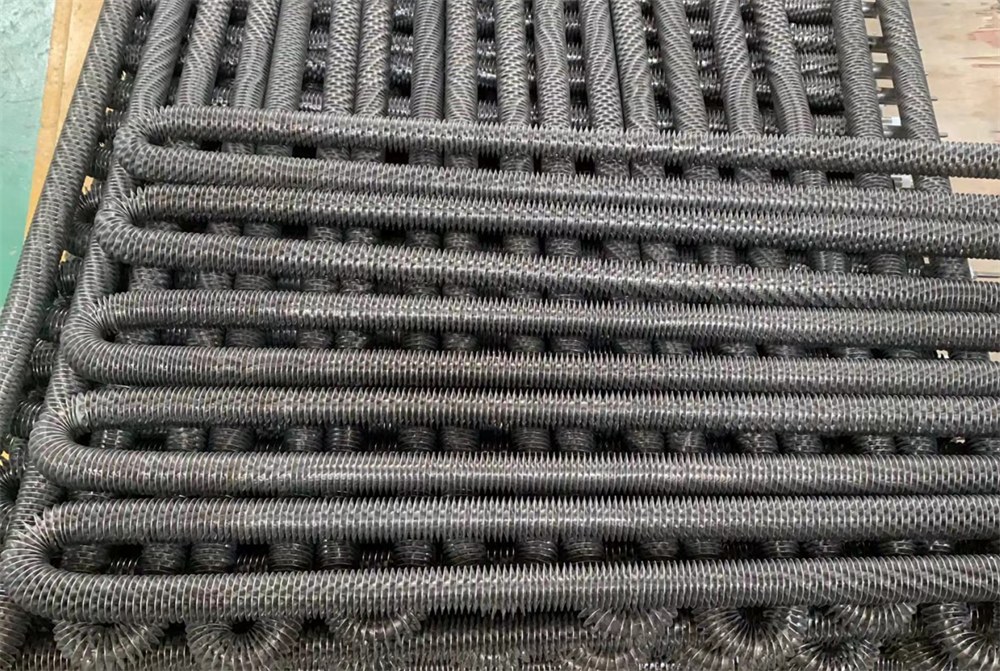

The core part of the load bank, the dry load module can convert electrical energy to thermal energy, and conduct continuous discharge testing for equipment, power generator and other equipment. Our company adopts a self -made alloy resistance composition load module. For the characteristics of dry load safety, it is easily affected by temperature, and strict quality control is adopted in terms of temperature coefficient and heat dissipation performance. Full load work is more heat -resistant and can work stable for a long time.

The specific technical solutions and goals are as follows:

1.Metal resistance wire material is selected from high temperature resistance (up to 1300 ℃), stable electrical performance, and small temperature drift coefficient (5*10-5/℃) nickel chromium alloy (NICR6023). At present, it stands for the most advanced alloy resistance manufacturing level.

2.The materials of each component of the power consumption resistance have strict regulations. The tube body adopts stretching and high antioxidant stainless steel 321 (1CR18NI9TI). It is JBY-TE4088-199. During the manufacturing process, the density value of magnesium sand is 3.0g/cm3 ±0.2, and the wiring screw and fixed screw column adopt corrosion-resistant and high-temperature stainless steel 321 (1CR18NI9TI). Through strict and clear material control, the alloy resistance of batch production can be guaranteed to have a high degree of consistency.

3.The heat sink is 321 with a height of 7mm ±2 and a thickness of 0.4mm ± 0.2.

4.The resistance voltage of single -rooted power consumption resistance is DC3000V or AC1500V, and 50Hz does not break through. Through multiple alloy resistors, it can ensure that the voltage resistance value reaches 20kV.

5.The average temperature of the heat sink of the alloy resistance under normal working state is ≤300 ℃, the maximum is 320 ℃, and the maximum temperature of the distance is nearly 5 times the fever of the maximum resistance of 1300 ℃ .

6.When the power resistance reaches 300 ℃ -400 ℃, the temperature drift is still ≤±2%, which ensures that the load resistance value will not have great fluctuations under the high temperature state power value.

7.Regardless of cold and hot, and the load error ≤±3%.

8.The air outlet temperature of the whole machine is ≤80 ℃ (1m range).

Post time: Aug-22-2022